-

Fundamental challenges of Toyota’s JIT system

-

Disaster Recovery: A need based on human experience

The Chernobyl disaster in April 1986 is considered one of the most severe environmental and human crises caused by human technology. This incident occurred at the Chernobyl Nuclear Power Plant in Ukraine (then part of the Soviet Union) when a catastrophic explosion, triggered by human errors and reactor design flaws, released massive amounts of radioactive materials into the atmosphere. The resulting radiation not only caused direct deaths and severe illnesses such as cancer among workers and nearby residents but also contaminated vast areas of soil, water, and air, affecting large parts of Europe. The evacuation of the city of Pripyat and the establishment of the “exclusion zone” for decades after the disaster symbolize the long-term consequences of technological catastrophes. Notably, the Soviet government suppressed news of the disaster for several days, which led to extensive secondary casualties due to the spread of harmful radiation among the public.

-

Role of Chief Risk Officer (CRO) or Secretary of Crisis Management/Disaster Management/Business Continuity Committee

Given the increasing and various risks imposed on organizations, the importance of the field of risk management/crisis management/disaster management is becoming increasingly sensitive. Many of our organizations/companies/industrial/petrochemical plants and refineries have not yet defined the position of CRO and still see the crisis within the framework of HSE and the like, while the Security, IT and OT fields also require their own measures. However, who should be the secretary of such a field in organizations/industrial companies/banks/holdings? Based on the events and experiences gained, a person should be chosen for this responsibility who, firstly, is completely in control of the fields that fall under this section and, secondly, is a very conservative person. You may be surprised by the word conservative, but a conservative person considers all aspects of the matter and his/her best efforts are to avoid creating a crisis in the company or organization. In fact, such a person always tries to take preventive measures with the measures he takes, which is the purpose of creating this area.

Chief Risk Officer

-

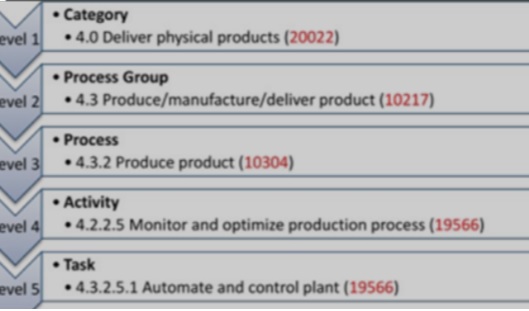

Digital transformation based on information technology governance in the IT field of automotive companies

Digital transformation in companies has now become a necessity. To achieve digital transformation in the field of information technology of organizations, ISO 38500 has been proposed. This ISO has set forth requirements that, without mentioning any solution, simply specify what should be achieved in the field of IT. To achieve the requirements set forth in this standard, a series of other standards/frameworks are needed, including COBIT, ISMS, TOGAF, ITSM, and BCM. The scope of these standards and frameworks is such that, depending on the organizational maturity and organizational culture of the relevant company, it will take years to implement all of them. Fortunately, APQC is a specific framework for the automotive sector that lists the minimum requirements for achieving the requirements of IT governance in the automotive sector in an Agile manner. In this way, based on the organizational structure of the relevant automotive company and the requirements, a roadmap can be prepared to achieve governance requirements based on business needs, stakeholder strategy, and upstream requirements, and move towards increasing the maturity of digital governance in the automotive IT field.

-

Iran, the biggest victim of cyber attacks in the world

Not long ago, at a national conference, I said that we are the world’s biggest victim of cyberattacks. “Really?” one of the audience members asked in surprise. I said yes! You may recall that one of the most famous and sophisticated of these attacks was the Stuxnet malware, discovered in 2010. Designed specifically to target industrial control systems at Iranian nuclear facilities, this attack is considered the first physical cyberattack (with a direct impact on industrial equipment). Stuxnet indirectly disrupted uranium enrichment centrifuges and represented a major development in cyberwarfare. Since then, Iran has repeatedly been the target of more sophisticated cyberattacks, including malware attacks such as Flame in 2012 and Shamoon in 2016. These attacks have often been linked to political, security, or the destruction of critical infrastructure in the country. In other words, countries were behind these attacks, attacks that went far beyond a hacker attack by an individual or a small group. Let’s take Business Continuity Management and Risk Management more seriously, especially in Iran. I will write more about this.

In strategic management and logistics courses, we used to talk about Toyota’s JIT method of sourcing its own parts as a sound strategy and an example, but in reality it was a double-edged sword with another edge:

In March 2011, the Tohoku earthquake and tsunami in Japan exposed the fundamental challenges of Toyota’s JIT system. Designed to reduce warehousing costs and increase efficiency, the system was extremely vulnerable to the crisis due to its heavy dependence on a limited number of suppliers and their geographic concentration in the affected areas. The destruction of key factories such as Renesas Electronics (which supplies 40% of the world’s automotive chips) caused monthly production stops at 50 Toyota plants and a 70% drop in production volume. JIT, which was based on “just-in-time supply,” could not prevent the production chain from stopping in the absence of emergency stocks or alternative suppliers.

The most important challenges of JIT in this crisis included the fragility of an over-optimized supply chain, its inflexibility to external shocks, and its critical dependence on parts produced in one region. Designed for normal conditions, this system not only increased the costs of production downtime when faced with unexpected disruptions, but also delayed recovery due to the time it took to identify new suppliers and set up alternative production lines.

Learning from the crisis, Toyota implemented significant structural reforms. These included creating strategic reserves of critical components (such as chips), diversifying suppliers geographically (collaborating with countries such as Thailand, China, and the United States), and strengthening early warning systems to monitor crises. In addition, the company increased the resilience of suppliers to natural disasters by training and providing financial support. These changes created a model combining JIT efficiency and flexibility that allowed for rapid response to future disruptions.

This experience is recognized as a turning point in Toyota’s supply chain management. Today, the company emphasizes not only “cost reduction” but also a balance between efficiency and resilience. Planning for crisis scenarios (such as pandemics or climate change), diversifying supply sources, and investing in disaster monitoring technologies are among the key lessons of this crisis that have made Toyota a global model in supply chain management.